NEXTEK-CI

your poultry partner

Feed is now 60% of the total cost of producing a broiler. Feed costs are forecast to remain high for the next 1-2 years*. Efficient feed utilization is the most influential input in the management of live production cost.

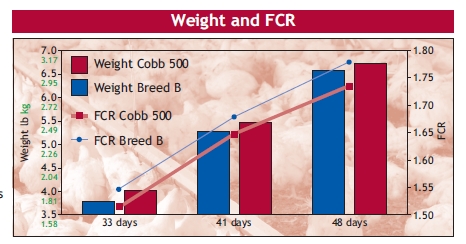

Cobb selection programs have emphasized efficiency and feed conversion as high priorities in the development of the Cobb 500. Cobb achieves the lowest cost of producing a kilogram or pound of meat in markets around the world.

Efficient feed conversion and excellent growth rate assist in the customer’s goal of achieving a target weight with the competitive advantage of lowest cost. Cobb combines both attributes in the world’s most successful broiler, the Cobb 500.

Cobb selection programs have emphasized efficiency and feed conversion as high priorities in the development of the Cobb 500. Cobb achieves the lowest cost of producing a kilogram or pound of meat in markets around the world.

Efficient feed conversion and excellent growth rate assist in the customer’s goal of achieving a target weight with the competitive advantage of lowest cost. Cobb combines both attributes in the world’s most successful broiler, the Cobb 500.

The world most efficient...

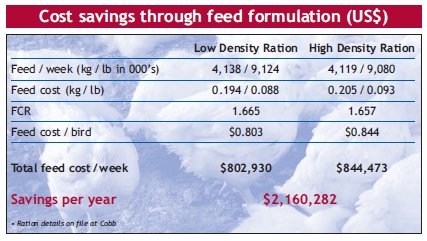

Lowest feed conversion together with the ability of the Cobb 500 to thrive on lower density, less

expensive feed, reduces the cost of producing chicken meat. When lower density feed with reduced nutrient levels is fed to the Cobb 500 it decreases feed ingredient costs without affecting performance.

Feed cost savings from a one million bird/week operation are over $2 million/year.

expensive feed, reduces the cost of producing chicken meat. When lower density feed with reduced nutrient levels is fed to the Cobb 500 it decreases feed ingredient costs without affecting performance.

Feed cost savings from a one million bird/week operation are over $2 million/year.

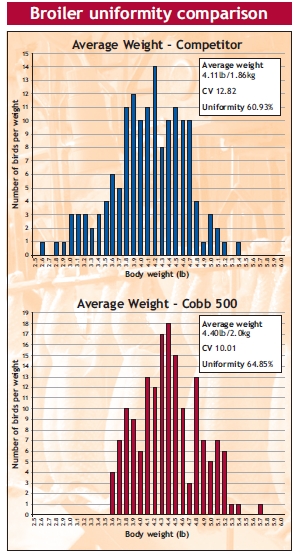

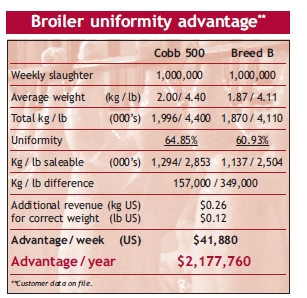

The Cobb 500 Broiler has the best uniformity in the market. The higher uniformity gives the processor more birds within a target weight specified by the customer.

The greater number of marketable broilers, the higher the sales revenue, optimizing customer revenue and profitability.

The greater number of marketable broilers, the higher the sales revenue, optimizing customer revenue and profitability.

Feed savings combined with uniformity advantages give over $4.3 million/year improvement in the bottom line for a million broiler/week operation.

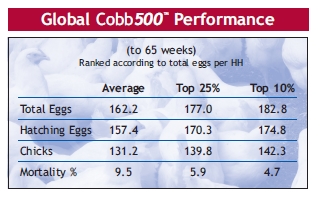

The Cobb 500 is a competitive breeder, providing excellent egg and chick numbers to complement the superior performance of the world’s most efficient broiler.

Copyright © 2010 www.nextekci.com • All Rights reserved • E-Mail: info@nextekci.com